🎄 Christmas Dispatch Notice

Please note that Clever Shield will be closed for the Christmas period starting from Friday 19 December 2025.

-

Last dispatch before Christmas:

• Wykamol products: Friday 19 December, 11AM

• Newton products: Monday 22 December, 2PM

• All other products: Thursday 18 December, 1PM - Orders placed during the Christmas closure will be dispatched from Friday 2 January 2026.

To avoid delays, we recommend placing your orders as early as possible.

Thank you for your continued support. We wish you a Merry Christmas and a Happy New Year!

Description

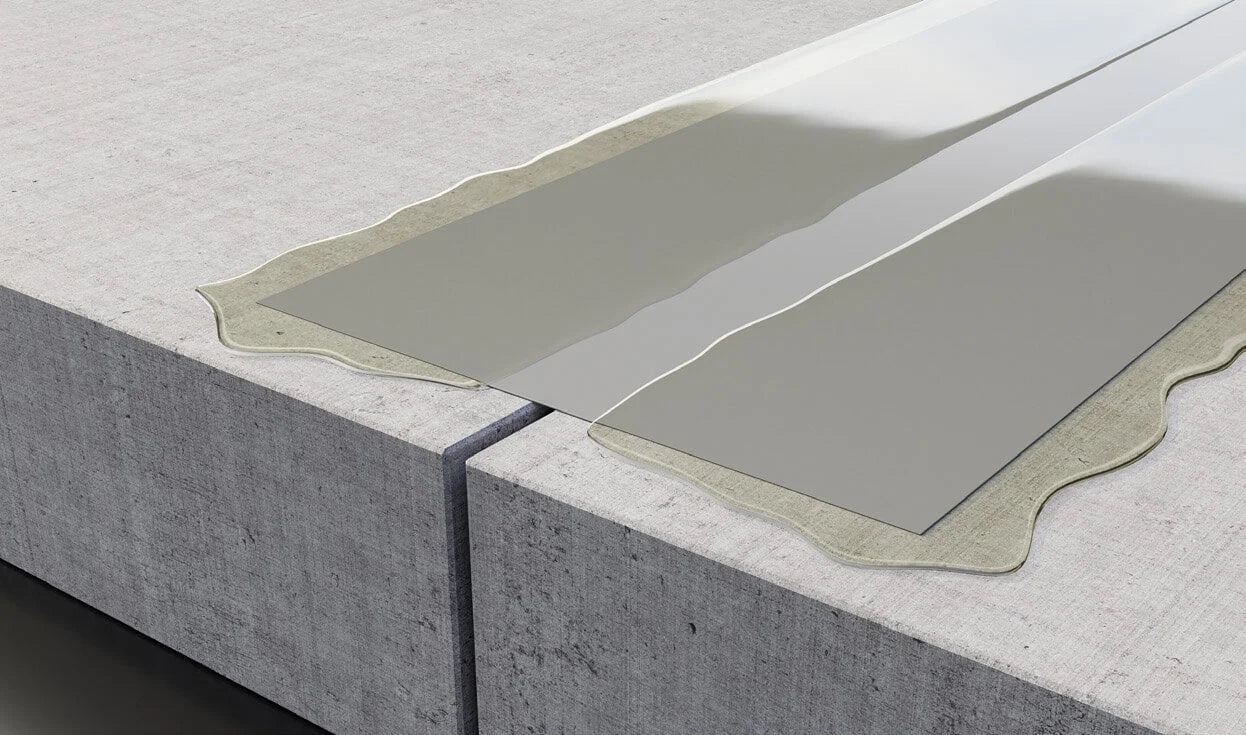

HydroSeal Monoflex – High-Performance Joint Sealing System

HydroSeal Monoflex is a flexible, durable joint sealing system designed for construction, movement, and expansion joints in below-ground and water-retaining structures. Engineered for critical areas with frequent or high movement, HydroSeal Monoflex maintains a permanent waterproof seal while accommodating structural shifts.

The system consists of:

✔ HydroSeal Monoflex Waterproofing Tape – A flexible polyolefine (FPO) tape with superior waterproofing and tear resistance

✔ HydroSeal Monoflex Adhesive – A two-component, solvent-free epoxy adhesive that ensures strong bonding to dry and damp substrates

Key Benefits:

HydroSeal Monoflex Waterproofing Tape

✅ Waterproofs construction joints – Resistant to ≥ 4.0 bar water pressure

✅ Highly flexible – Accommodates extreme movement without failure

✅ Easy and quick to install & repair – Minimal downtime

✅ Excellent adhesion – Bonds securely to concrete, masonry & steel

✅ Applicable on damp concrete – No need for extensive drying

HydroSeal Monoflex Adhesive

✅ No primer required – Bonds directly to most building materials

✅ Superior adhesion to damp & dry substrates

✅ Low odour, solvent-free formulation – Safe for confined spaces

✅ Resistant to weathering, water & chemicals – Ensures long-lasting performance

✅ Colour-coded components – Ensures correct and easy mixing

Typical Applications:

✔ Sealing construction & movement joints

✔ Pipe penetrations & cracks

✔ Basements & tunnels

✔ Sewage & water treatment plants

✔ Swimming pools & hydroelectric plants

✔ Culverts & earth-retained structures

Technical Performance:

HydroSeal Monoflex Waterproofing Tape

| Property | Result |

|---|---|

| Material | Flexible polyolefine (FPO) |

| Thickness | 1.0 mm |

| Tear Resistance (Lengthwise & Across) | 15 N/mm² |

| Elongation at Break (Lengthwise) | 620% |

| Elongation at Break (Across) | 670% |

| Water Vapour Permeability | 60 m |

| UV Resistance | ≥ 6500 h |

| Bonding Strength | ≥ 4.0 N/mm² |

| Water Tightness (60 kPa/24 hrs, 400 kPa/72 hrs) | Watertight |

| Burst Pressure | ≥ 4.0 bar |

| Reaction to Fire | Class E |

HydroSeal Monoflex Adhesive

| Property | Result |

|---|---|

| Form | Two-component liquid epoxy |

| Colour | Light grey |

| Specific Gravity | 1.5 g/cm³ |

| Application Temperature Range | +3 to +30°C |

| Curing Time (20°C) | 10-12 hours |

| Compressive Strength (1 day) | 40 MPa |

| Compressive Strength (7 days) | 75 MPa |

| Tensile Strength | 18 MPa |

| Lap Shear Strength (To Grit Blasted Steel) | 14 MPa² |

| Shrinkage on Curing | Negligible |

Product Variants & Packaging:

HydroSeal Monoflex Tape

- HS-MF-100: 100 mm x 20 m roll (2m²)

- HS-MF-200: 200 mm x 20 m roll (4m²)

HydroSeal Monoflex Adhesive

- HS-MFA: 5 kg (two-container pack)

💪 Ensure long-lasting waterproofing for movement & expansion joints with HydroSeal Monoflex – Order today!

Downloads

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Security

You may also be interested in

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer