Vapour Control Layers (VCLs)

10 products

Showing 1 - 10 of 10 products

Vapour Control Layers (VCLs) – Essential for Moisture Management & Energy Efficiency

Vapour Control Layers (VCLs) are crucial components in modern building construction, designed to regulate moisture movement, improve thermal efficiency, and maintain indoor air quality. By controlling the diffusion of water vapour, VCLs prevent condensation, reducing the risk of mould growth and structural deterioration.

Benefits of Vapour Control Layers:

✔ Moisture Management – Prevents water vapour ingress and reduces condensation-related damage.

✔ Energy Efficiency – Minimises heat loss, stabilising indoor temperatures and lowering energy consumption.

✔ Improved Air Quality – Controls humidity levels, preventing mould and mildew growth for a healthier environment.

Types of Vapour Control Layers:

- Polyethylene Films – High-resistance plastic membranes used in walls, floors, and roofs.

- Bituminous Membranes – Durable, waterproof layers ideal for flat roofs and below-ground applications.

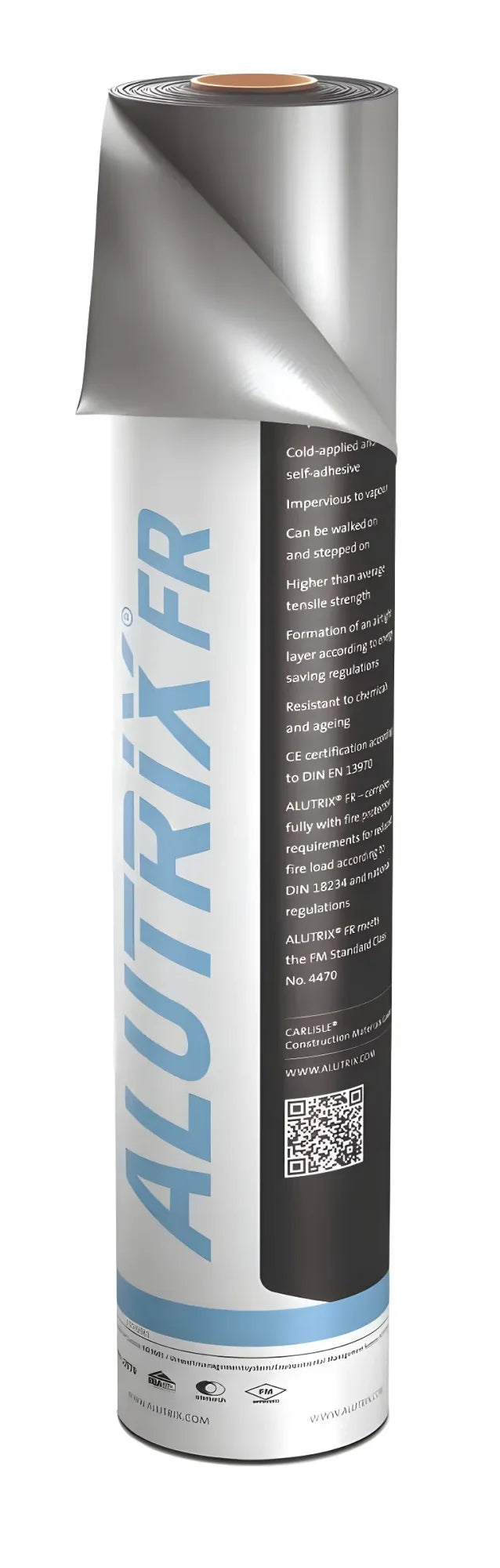

- Metal Foils – Vapour-tight aluminium sheets that enhance insulation performance.

- Specialised Coatings – Liquid-applied vapour barriers for concrete, wood, and masonry surfaces.

Correct Installation for Maximum Performance:

✅ Sealing – Ensuring airtight joints, seams, and penetrations with tapes, adhesives, or sealants.

✅ Proper Placement – Positioned on the warm side of insulation to prevent internal condensation.

✅ Integration with Other Components – Designed to work with windows, doors, and ventilation systems without compromising efficiency.

Clever Shield offers high-performance Vapour Control Layers, ensuring long-lasting protection, improved thermal performance, and a healthier indoor environment for all building types.

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer