Pipe Protection & Refurbishment

32 products

Showing 1 - 32 of 32 products

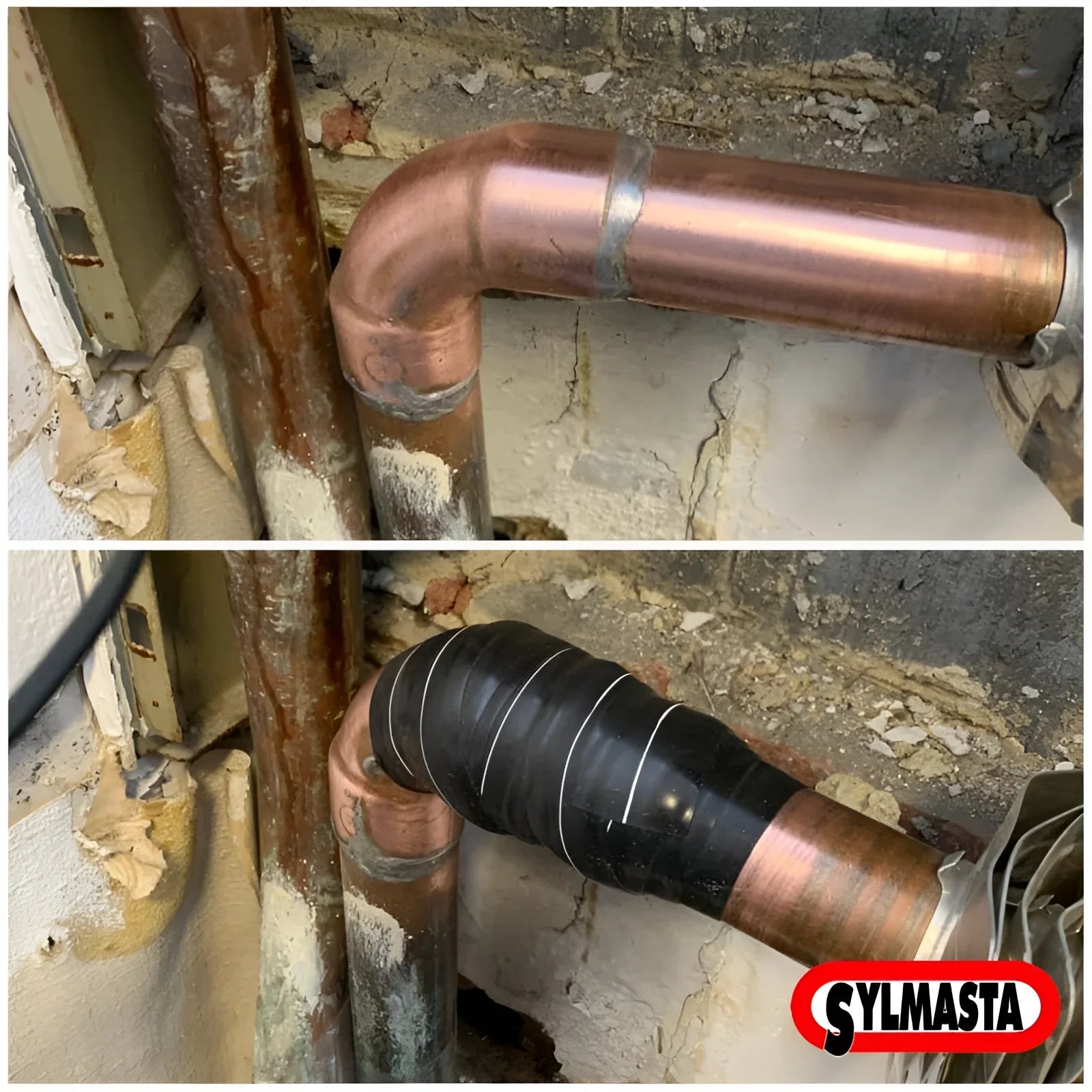

The Sylmasta Pipe Refurbishment System is a four-stage process which is designed to repair, refurbish, strengthen and protect pipelines in any given scenario.

You select the most relevant product to your application from each stage of the process. When used in conjunction with each other, these products enable the optimum repair to be carried out.

Leak Sealant

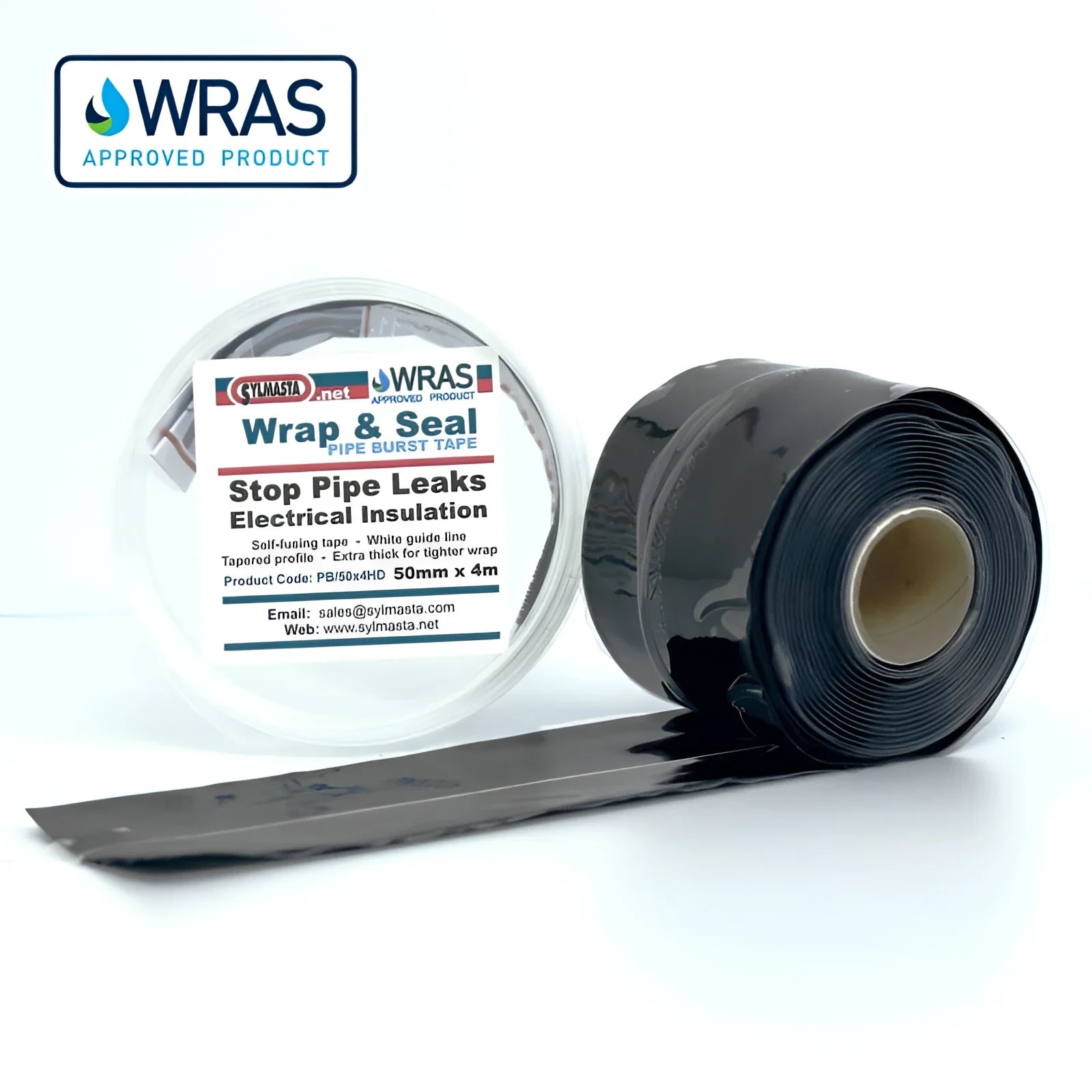

Leak Sealants are used to repair holes and cracks in pipes. Epoxy putties are used for when water pressure can be turned off and Wrap & Seal Pipe Repair Tape for live leaks. If your pipe is not leaking, then this stage of the process is skipped.

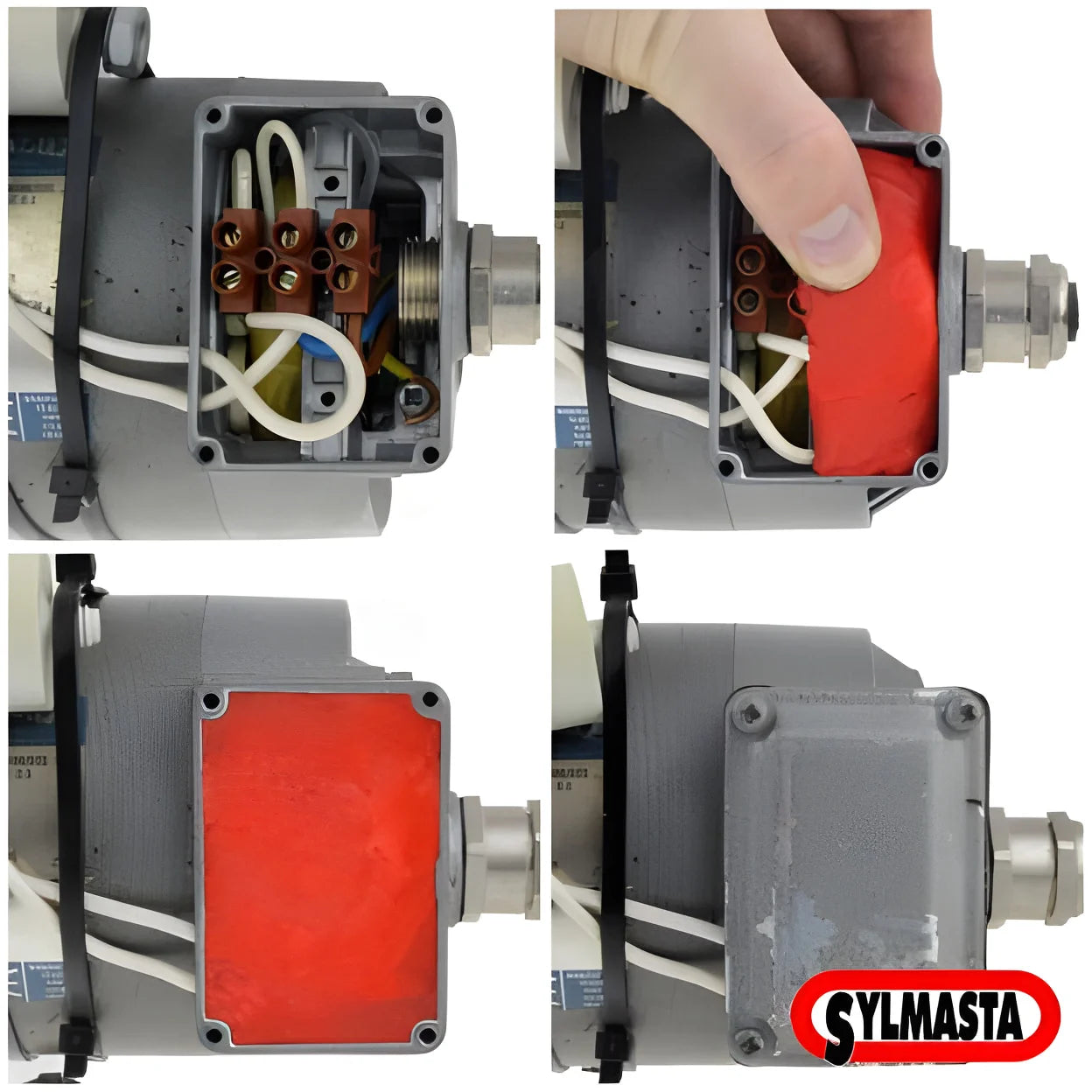

Damage Repair

Damage Repair products restore the integrity of the pipeline by repairing external damaged caused by problems such as corrosion. They consist of epoxy putties and pastes which also provide full contact and load spreading between the pipe surface and the composite layer of the repair at stage 4.

Surface Coating

The Surface Coating provides an extra layer of corrosion protection, maximises surface contact area with the composite shell, increases adhesion, and provides an additional impermeable membrane in the event of a future breach of the original pipe due to internal corrosion. If the user is satisfied that leaks caused by internal corrosion will not occur or if the exterior pipe surface is in sufficiently good condition to be wrapped directly over with the composite layer, then this stage can be skipped.

Composite Wrap

The final stage of the Sylmasta Pipe Refurbishment System involves reinforcing the previous stages of repair and increasing the hoop strength of the pipe, and therefore the pressure resistance. This is done with either SylWrap Composite Repair Wraps, or for more complex and technical applications, a Sylmasta E190 Epoxy Composite Repair.

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer