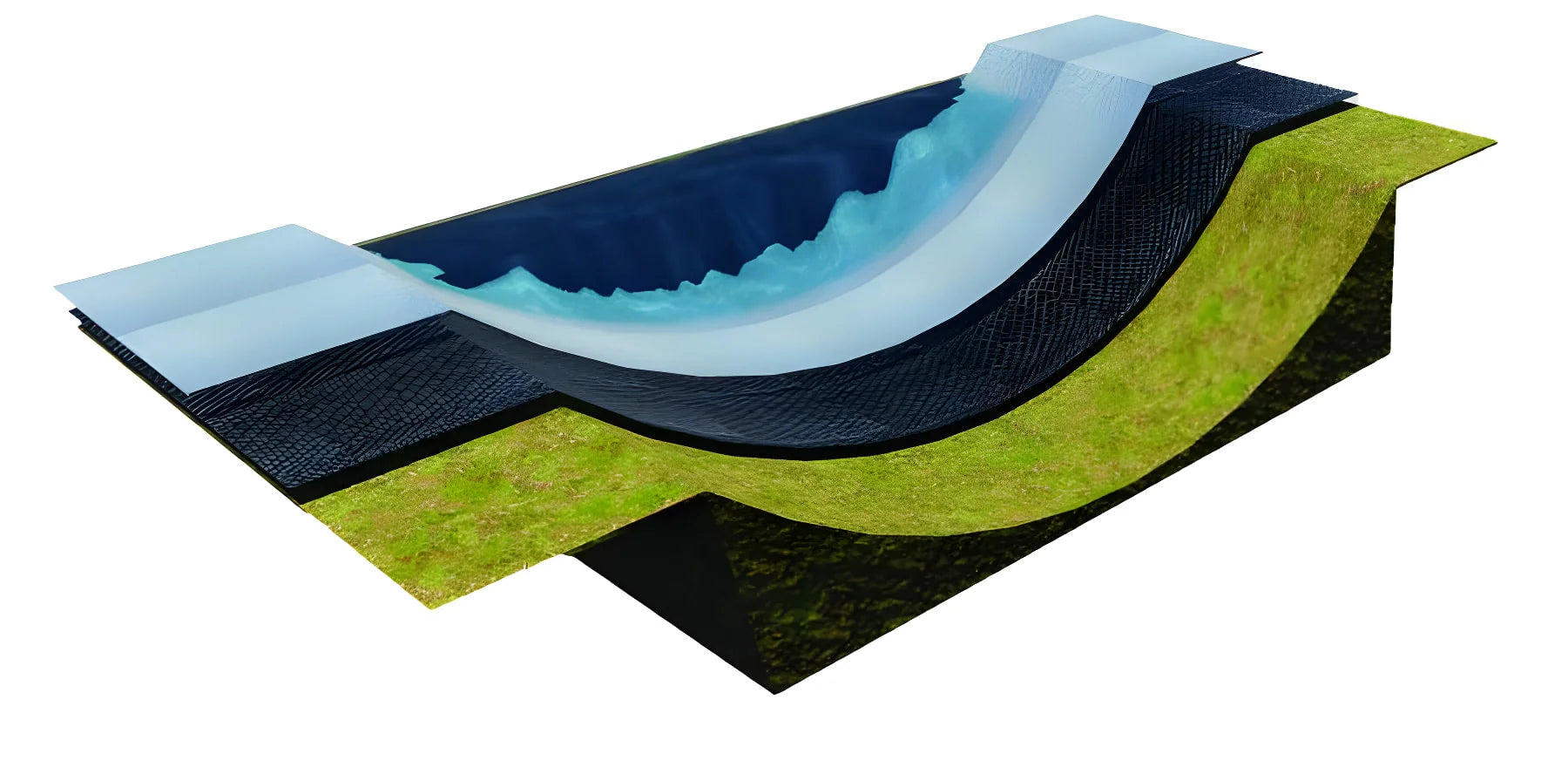

Water Containment

35 products

Showing 1 - 35 of 35 products

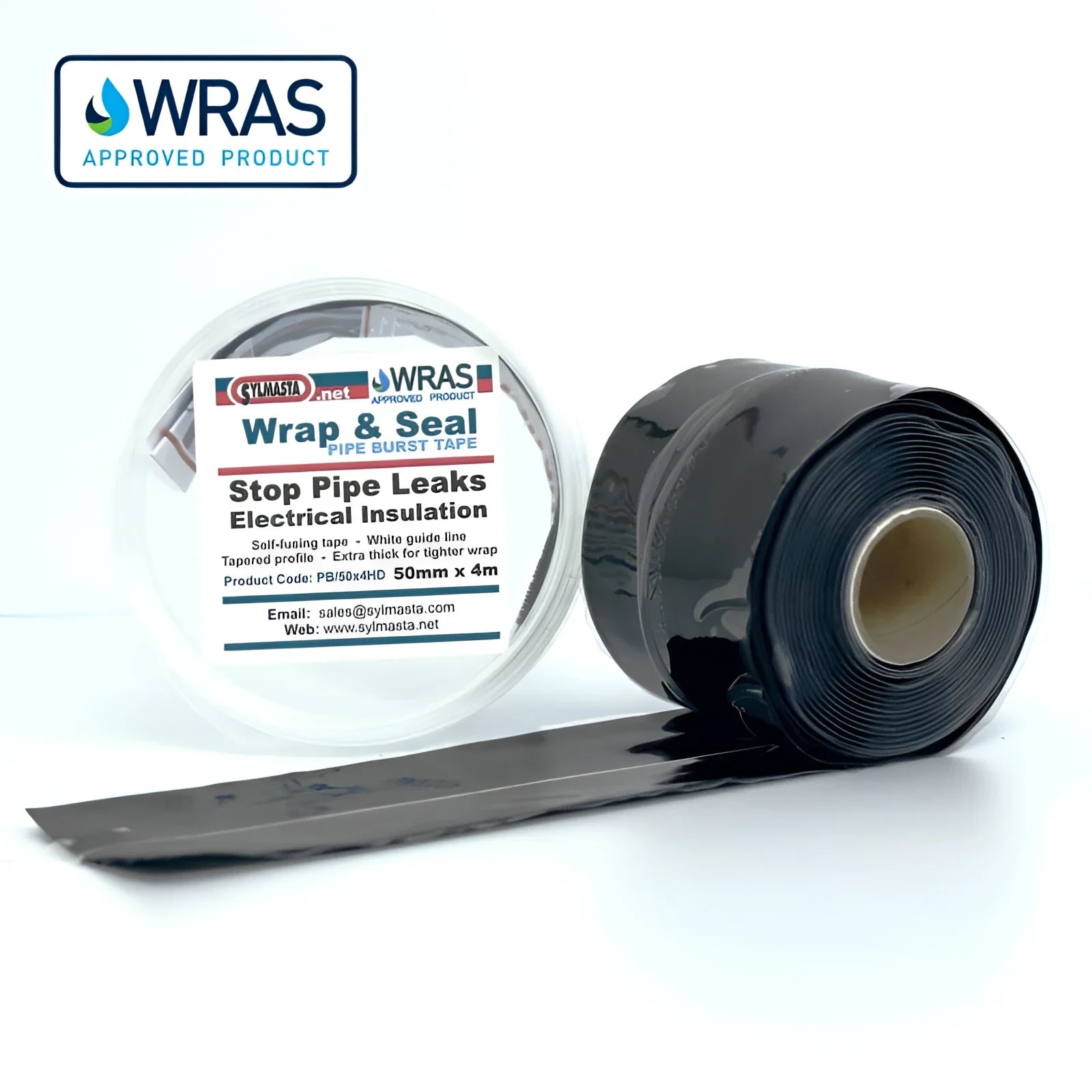

DWI & WRAS Approved Waterproofing Solutions – Safe & Certified Protection for Water & Wastewater Assets

Clever Shield provides industry-leading DWI and WRAS-approved waterproof coatings for potable water and wastewater applications, ensuring safe containment, durability, and compliance with international standards.

Our solutions include high-performance polyurea coatings, cementitious waterproofing systems, and polymer-modified waterproof membranes, designed to protect reservoirs, water tanks, ponds, and aquatic systems.

Certified Waterproofing for Drinking Water & Industrial Use

✔ DWI & WRAS Approved – Compliant with global standards for safe water containment.

✔ Versatile Applications – Ideal for reservoirs, water tanks, fish farms, fountains, and wastewater treatment plants.

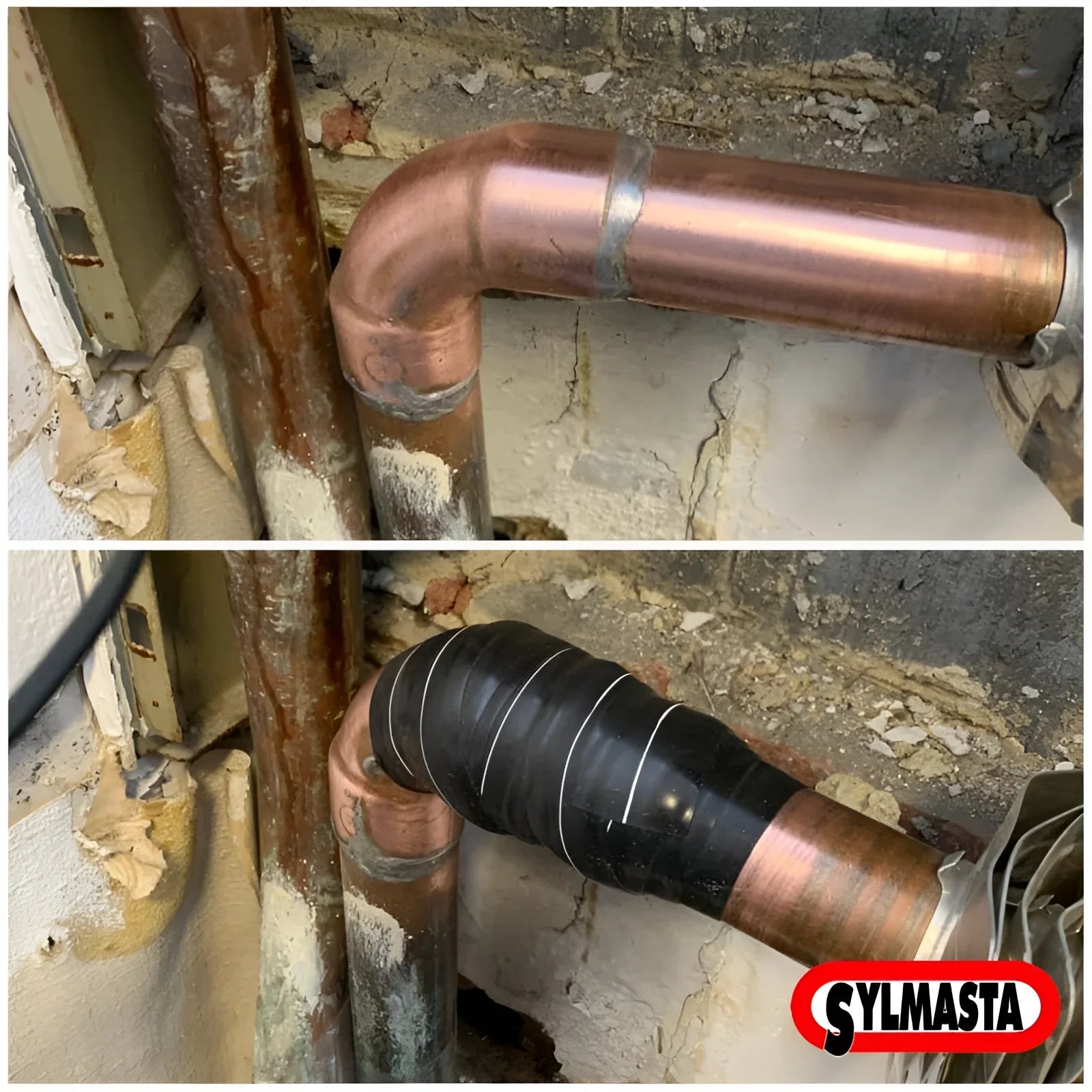

✔ Seamless, High-Performance Protection – Prevents leaks, cracks, and contamination risks.

✔ Fast-Curing & Durable – Rapid return-to-service, minimizing downtime.

Polyurea Waterproofing – Ultimate Protection for Water & Wastewater Assets

1. QuickSpray Supreme W & Industrial W Polyurea – WRAS & DM 174 Certified

✔ How It Works – Spray-applied, seamless, and flexible membrane with instant curing.

✔ Ideal For – Potable water reservoirs, storage tanks, de-salination plants, and fish farms.

✔ Benefits –

- High-impact & abrasion resistance – Withstands harsh environmental conditions.

- Long life-cycle – Low maintenance costs and extended durability.

- Fast reactivity – Cures within seconds, allowing a quick return to service (48 hours max).

- 100% solids, VOC-free, solvent-free – Safe for drinking water applications.

- Compatible with concrete, steel, fiberglass, wood, and foam.

💡 Global Potable Water Approvals: WRAS (UK), KTW (Germany), KIWA (Sweden), plus certifications in Australia, New Zealand, Norway, Poland, South Africa, and Singapore.

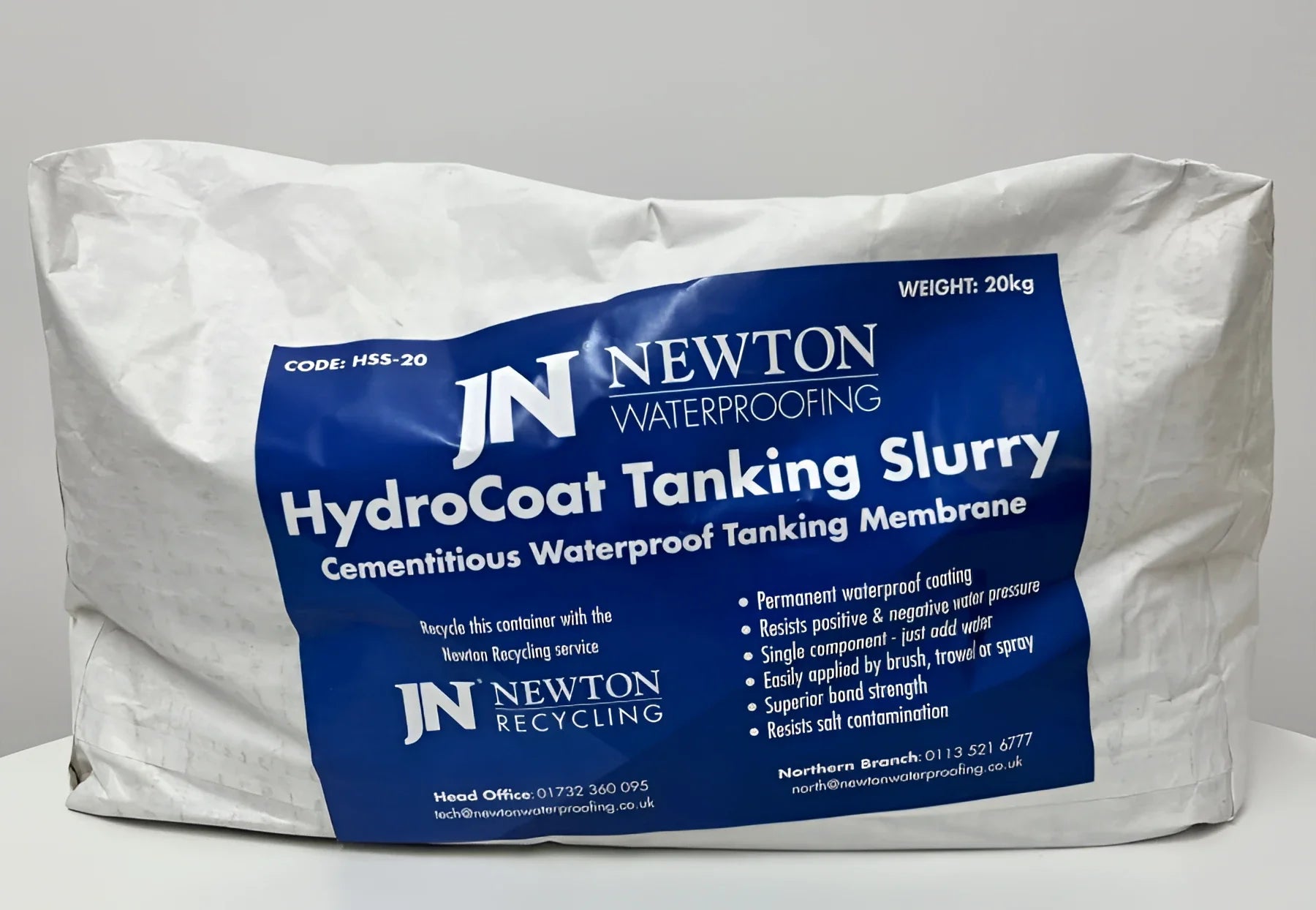

Cementitious Waterproofing – Permanent Protection for Concrete & Masonry

2. Wykamol Hydradry Tanking Slurry

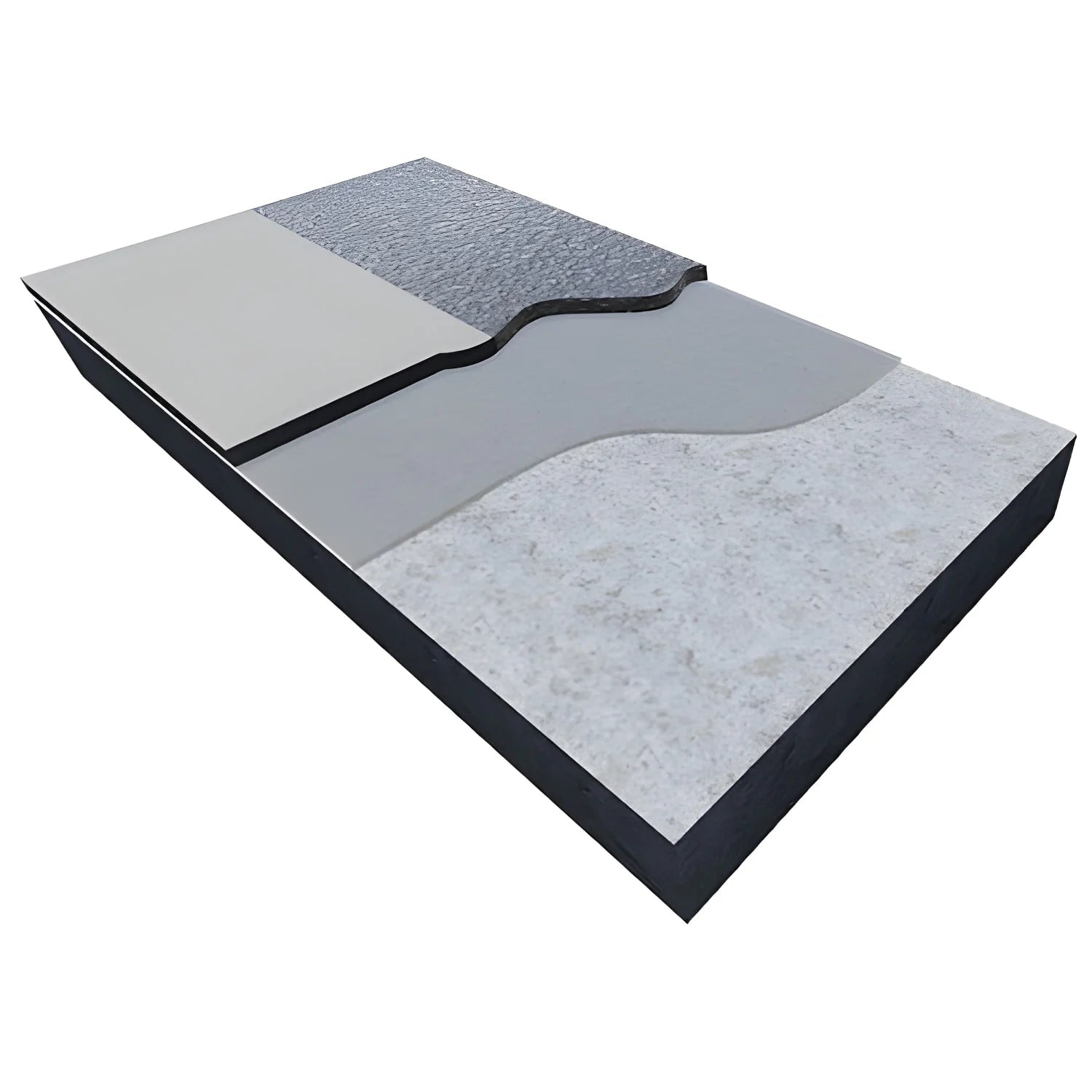

✔ How It Works – Crystalline cementitious waterproofing slurry, forming a monolithic bond to concrete and masonry.

✔ Ideal For – Waterproofing potable water tanks, reservoirs, and below-ground structures.

✔ Benefits –

- Resists positive & negative hydrostatic pressure – Prevents water ingress & leakage.

- Superior adhesion & permanent waterproofing – Ensures long-lasting durability.

- WRAS Approved – Safe for direct contact with drinking water.

- Prevents migration of hygroscopic salts – Reduces damp and contamination risks.

💡 For aquatic life containment, overcoat Hydradry Tanking Slurry with Wykamol Technoseal DPM for full protection.

SilaCote ST Polymer Coatings – Ideal for Ponds, Fish Farms & Water Features

✔ How It Works – Liquid-applied silicone membrane, fully reinforced with air mesh membrane for enhanced performance.

✔ Ideal For – Ponds, fountains, water features, and aquatic environments.

✔ Benefits –

- Cold-applied & fast-curing – Can be applied even on damp surfaces.

- Bridges cracks & accommodates movement – Prevents leakage and structural damage.

- Solvent-free & VOC-free – Safe for marine life, fish farms, and decorative water features.

- BBA & ETAG Compliant – Meets strict European waterproofing standards.

Why Choose Clever Shield for DWI & WRAS Approved Waterproofing?

✔ Global Certification & Compliance – WRAS, DM 174, KIWA, & KTW certified solutions.

✔ Long-Term Protection – UV-resistant, impact-proof & highly durable coatings.

✔ Versatile for All Water Containment Applications – Suitable for public, commercial & industrial projects.

✔ Expert Technical Support – Our specialists provide consultation & tailored recommendations.

Get a Quote for Professional Waterproofing Application Today!

Ensure compliant, long-lasting waterproofing for potable water storage, wastewater management, and aquatic environments with Clever Shield’s certified solutions.

📞 Need expert advice? Contact us today for tailored recommendations!

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer