Description

MAPEI CARBOPLATE E – Pultruded Carbon Fibre Plates for Structural Strengthening

CARBOPLATE E is a high-strength, pultruded carbon fibre plate system for structural upgrading of reinforced concrete, steel and wooden members. It increases flexural capacity, supports seismic upgrading in high-risk areas, and installs rapidly with epoxy adhesives, often without taking structures out of service.

Products Used in the System

Carboplate E170 · Carboplate E200 · Carboplate E250 · MapeWrap 11 · MapeWrap 12 · Adesilex PG1 · Adesilex PG2

Where to Use

-

Repair & static upgrading of RC beams, floor joists and slabs (flexural strengthening)

-

Flexural strengthening of wooden beams/joists

-

Repairs after fire or earthquake damage

-

Renovation of two-dimensional elements (plates, sheets, tanks with large radius)

-

Viaduct deck strengthening after increased static/dynamic loads

-

Industrial/commercial structures after load increases (new machinery/equipment)

-

Vehicle access ramps; structures subject to vibration

-

Load-bearing members modified by new architectural layouts or change of use

Advantages

-

Fast installation: extremely light; no special machinery; minimal downtime

-

No corrosion risk: unlike metal plating (béton plaqué); no temporary supports needed

-

Quality & speed vs. on-site fabrics: quicker, less operator-dependent

-

Conforms to principles of EN 1504-9 and requirements of EN 1504-4 (structural bonding)

-

Flexible application: suitable for cylindrical elements (≥3 m bending radius)

Technical Characteristics (System)

-

Plate types: E170 (low-modulus), E200 (medium-modulus), E250 (high-modulus)

-

Typical properties (system): high tensile strength, lightweight, compact, excellent fatigue strength

-

Adhesives: MapeWrap 11 / MapeWrap 12 / Adesilex PG1 / Adesilex PG2 (two-component thixotropic epoxies)

-

Certification: Certificate of Technical Assessment No. 376/2022 (replaces No. 206/2019)

Available Sizes (Rolls 25 m)

-

E170: 50/100/150 mm widths × 1.4 mm thick

-

E200: 50/100/150 mm widths × 1.4 mm thick

-

E250: 50/100/150 mm widths × 1.4 mm thick

Application (Summary)

-

Substrate prep: clean, dry, sound, even (max roughness 1 mm); concrete tensile strength >1.5 MPa. Repair with Mapegrout range; protect steel with Mapefer / Mapefer 1K Zero. Prime absorbent/high-RH substrates with MapeWrap Primer 1.

-

Adhesive mixing: mix A+B (3:1 by weight) for MapeWrap 11/12 or Adesilex PG1/PG2 until uniform.

-

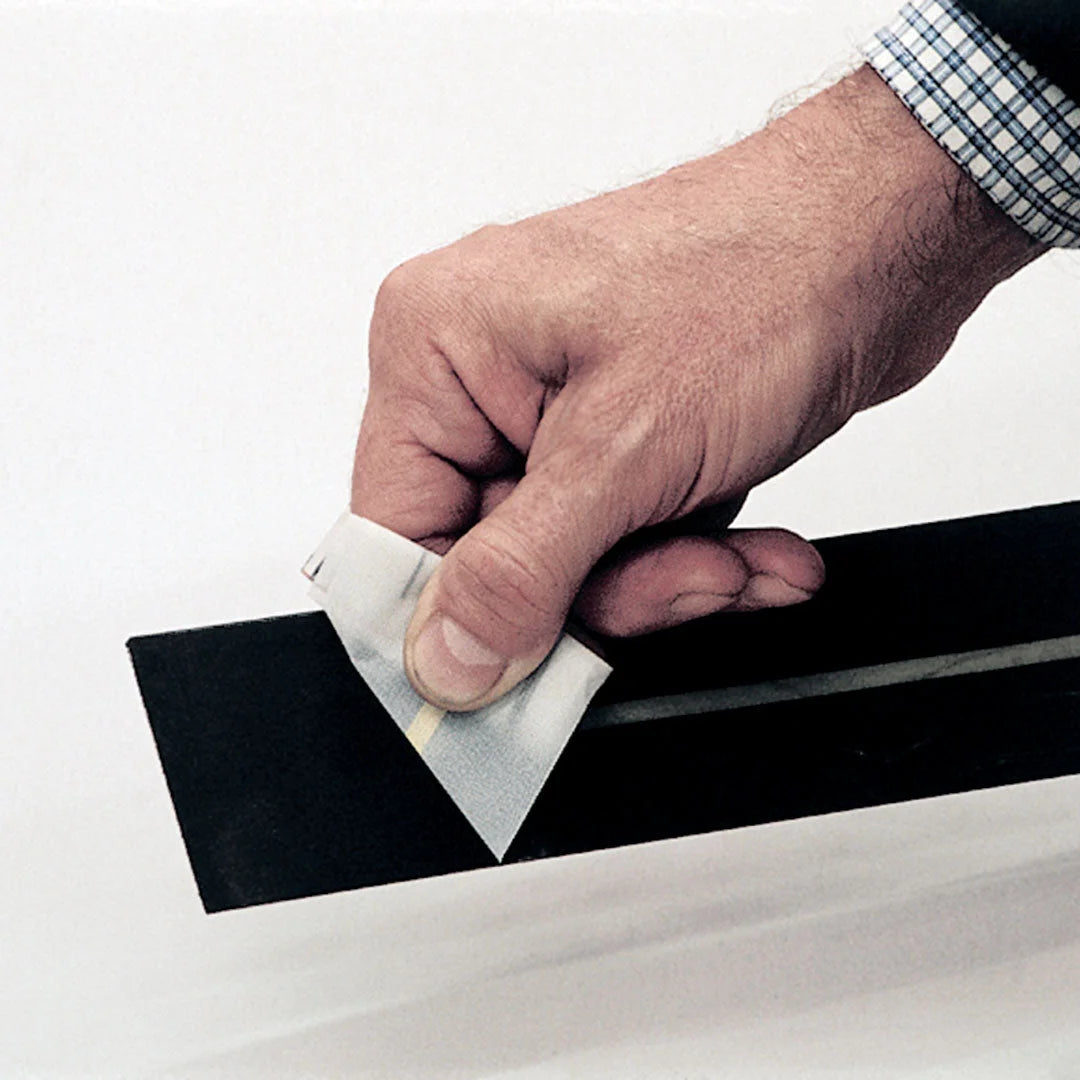

Bonding: remove peel-ply; apply 1–1.5 mm adhesive on plate and substrate (over wet primer); press plate uniformly with a rubber roller; remove excess resin. Use temporary clamps on curved elements until cure. For multilayers, remove upper peel-ply before next plate.

-

Finishing (optional): quartz-sand broadcast into fresh resin; finish with Planitop skim or protect externally with Mapelastic Zero; fire protection via cladding or intumescent render as specified.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Security

You may also be interested in

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer