Liquid Coatings - Material Cost and the Coverage

Having been asked many times how do we work out the true cost and coverage of a liquid coating.

In order to work out the material cost and the coverage of a liquid coating it is necessary to calculate and evaluate its properties.

Below are examples which explain coverage of materials and overall cost together with possible failure of materials that are not 100% Aliphatic / UV Stable.

After the coating is applied, the resin, pigments, additives (such as stabilisers, anti-foams and thickeners) and solvent (if included) evaporate, leaving only the dry SOLIDS in the form of a continuous coating.

The solids can be expressed as a volume percentage of the entire volume of the container (can/ tin) of material.

100% Solids - Makes a Real Difference to the Amount Material Needed to Achieve required Dry Film Thickness (DFT)

Example of coatings LESS than 100% Solids: -

If the resin, pigments, additives (such as stabilisers, anti-foams and thickeners) and solvent (if included) make up half the coating volume, then one can say that the coating is 50% solids.

One can therefore expect that if a wet coat of the material is applied to a wet film thickness of 2mm the dry film thickness (DFT) will be only 1mm (after the coating has cured).

In order to achieve the DFT of 2mm it would be necessary to apply a minimum of 4mm of wet material.

Example of coverage based on 100% Solids: -

With a material that has 100% solids you can apply 2mm wet film thickness and can rely on a 2mm DFT when cured.

Specific Gravity Makes a Real Difference to the Amount Material Needed to Cover an Area with Required Dry Film Thickness (DFT)

Example of coverage based on a specific gravity of 1 (water): -

To cover an area of 10m2 at 1mm you would require 10 Litres of water (which weighs 10KG) as its specific gravity is 1. Water has a density of 1 kg per litre (1 kg/l) which covers 1m2.

All liquid coatings will have a specific gravity higher than 1 as the weight of 1 litre of liquid coating will be heavier than water, typically 1.3 kg per litre, but it may be greater.

One can therefore say it will take 1.3 kg of material to cover 1m2 at 1mm or 13 kg to cover 10m2 at 1mm.

Example of coverage based on weight

Most manufacturers package liquid coatings by weight, typically 10, 20, 25 kg tins.

In order cover 10m2 at 1mm you would require 13 kg of material and to achieve the typical 2mm you would require 26 kg of material.

Note: For materials that are not 100% Solids and or contain plasticizers this figure is higher.

Brittle Coatings Prone to Cracking and Splitting

Most two-part roof coating systems contain plasticizers (the substance that is added to a material to give high elongation values and make it softer and more flexible).

When these coatings are exposed to UV (sunlight), the plasticizers migrate and evaporate eventually leaving the coating brittle and prone to cracking and splitting.

Additional Costs.

Nearly all liquid coatings require a primer and a top coat to protect against UV damage.

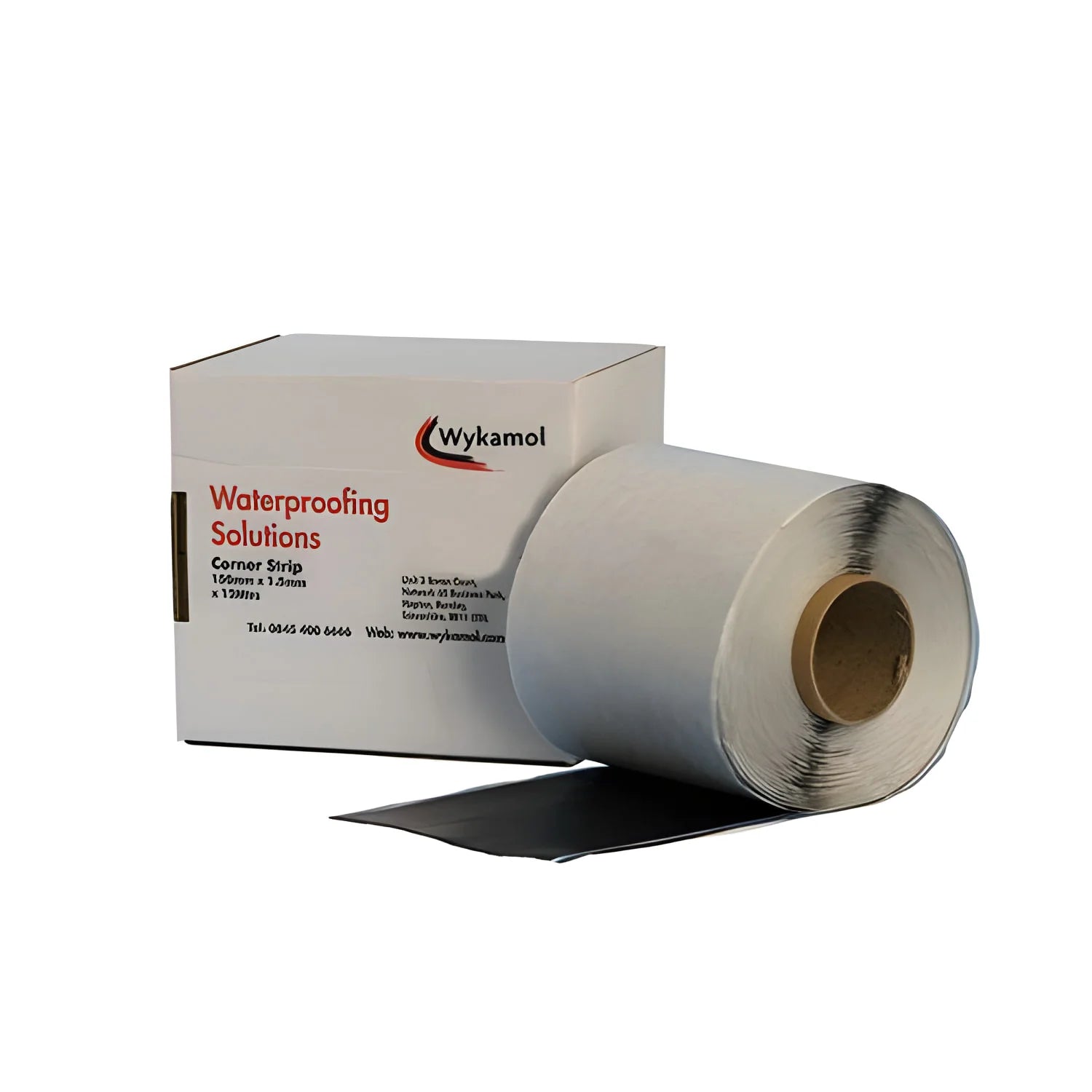

Our BEST Selling Waterproof Liquid Coating System this Year!

SilaCote is one of the few that NOT ONLY doesn’t require a top coat (100% Aliphatic) but also doesn’t require a primer. Its 100% Solids with no plasticizers.

EASILY HAND APPLIED - SOLVENT FREE – UNLIMITED OVERCOAT TIME – USE ONLY WHAT YOU NEED / NO WASTE - LIGHT FOOT TRAFFIK 1 HOUR - SAVES MONEY ON MATERIALS AND LABOUR