The Trident Thermatank Advantage

In the ever-evolving field of industrial tank insulation, Trident Thermatank Insulation stands out as a leader in innovation and efficiency. Their cutting-edge insulation panel systems are meticulously engineered to minimize heat loss or gain in storage tanks, ensuring stable temperatures for stored liquids and significantly reducing energy consumption. Trident’s advanced solutions cater to a diverse range of industries and applications, from thermal energy storage and crude oil to fermentation tanks and equipment like coke drums and hot boxes.

Advanced Insulation Solutions

Bespoke Design

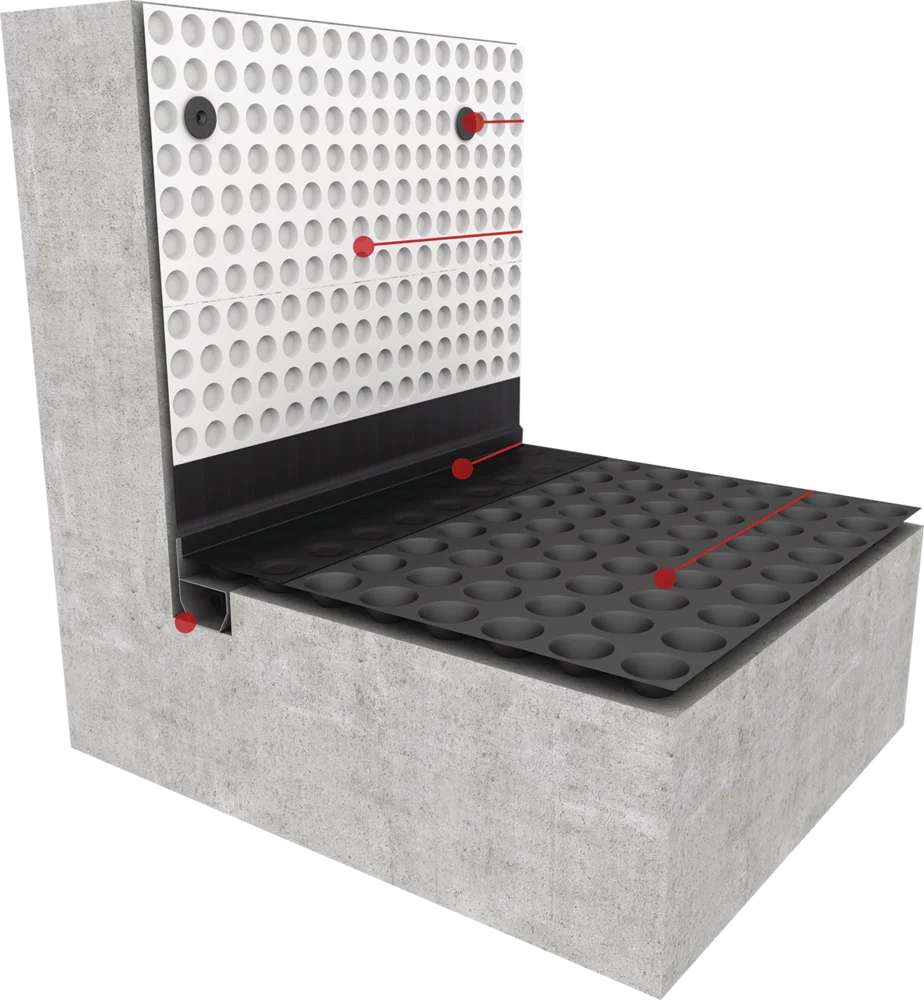

At the core of Trident Insulation’s offerings are their custom-designed pre-fabricated panels. These panels are engineered for exceptional thermal performance, ease of use, and durability. They feature a unique combination of closed-cell insulation material and metallic jacketing, which enhances their ability to reduce thermal bridging. Additionally, the panels are built with a double-locking vertical seam construction that not only boosts their structural integrity but also provides superior protection against environmental elements.

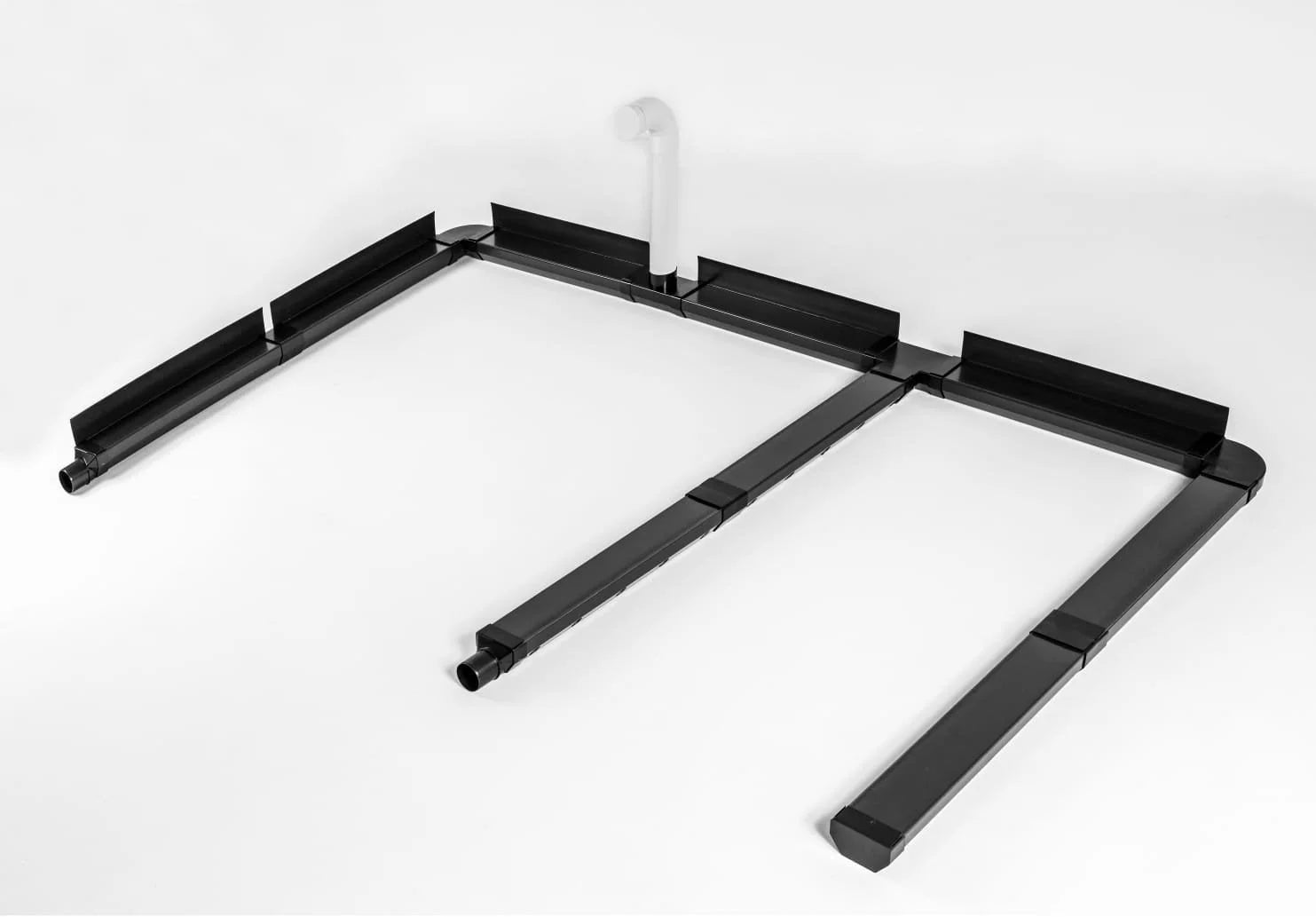

Simplified Installation

One of the standout features of Trident’s insulation panels is their simplified installation process. The rigid, pre-made panels are designed for easy attachment to industrial tanks with minimal scaffolding. This significantly reduces installation time and project schedules, lowering the total installed cost and minimizing logistical and labor challenges typically associated with traditional insulation methods. The streamlined installation process ensures that operations can continue with minimal disruption.

Superior Protection and Maintenance

Once installed, Trident’s insulation systems offer unparalleled rigidity and protection. The panels are designed to minimize moisture ingress and reduce the risk of under-insulation corrosion, a common issue in industrial environments. This high level of protection not only extends the lifespan of the tanks but also simplifies maintenance and inspection processes. The ease of maintenance ensures that operational efficiency is maintained and downtime is minimised, leading to long-term cost savings.

Thermal Performance Excellence

Trident Thermatank Insulation’s commitment to thermal performance is evident in their rigorous research and development efforts. They prioritise thermal efficiency, producing prototypes that meet stringent performance standards. To ensure their panels meet project-specific requirements, Trident provides detailed thermal efficiency reports prior to production. These reports give clients a clear understanding of how the insulation will perform under various conditions, ensuring optimal energy usage and cost savings.

Applications Across Industries

Trident Thermatank Insulation’s panels are versatile and suitable for a wide range of industrial applications. For thermal energy storage tanks, the insulation helps maintain the required temperatures for efficient energy use. In asphalt, crude oil, and sulfur tanks, the panels prevent temperature fluctuations that could affect the quality and handling of these materials. Beverage and fermentation tanks benefit from consistent temperatures crucial for product quality. Additionally, equipment like coke drums and hot boxes see improved thermal management, leading to better operational efficiency.

Leading the Way in Industrial Insulation

Trident Insulation is revolutionising the field of industrial tank insulation with their innovative panel systems. Their solutions not only enhance thermal performance and energy efficiency but also simplify installation and maintenance processes. By offering bespoke design, superior protection, and versatility across various industries, Trident Thermatank Insulation is setting new standards for what is possible in industrial insulation technology.

As industries continue to seek ways to improve efficiency and reduce energy consumption, Trident Thermatank Insulation remains at the forefront, providing solutions that meet the evolving needs of their clients while ensuring robust performance and long-term reliability.