Description

HydroTank 302 Injection Hose – High-Performance Resin Injection Waterbar

The HydroTank 302 Injection Hose is an advanced waterbar system designed for sealing construction joints in earth-retaining and water-retaining concrete structures. When injected with a compatible polyurethane or acrylic injection resin, the system permanently seals cracks, capillaries, pores, and honeycombing within the concrete structure, enhancing the water tightness of ‘Type B’ waterproofing systems.

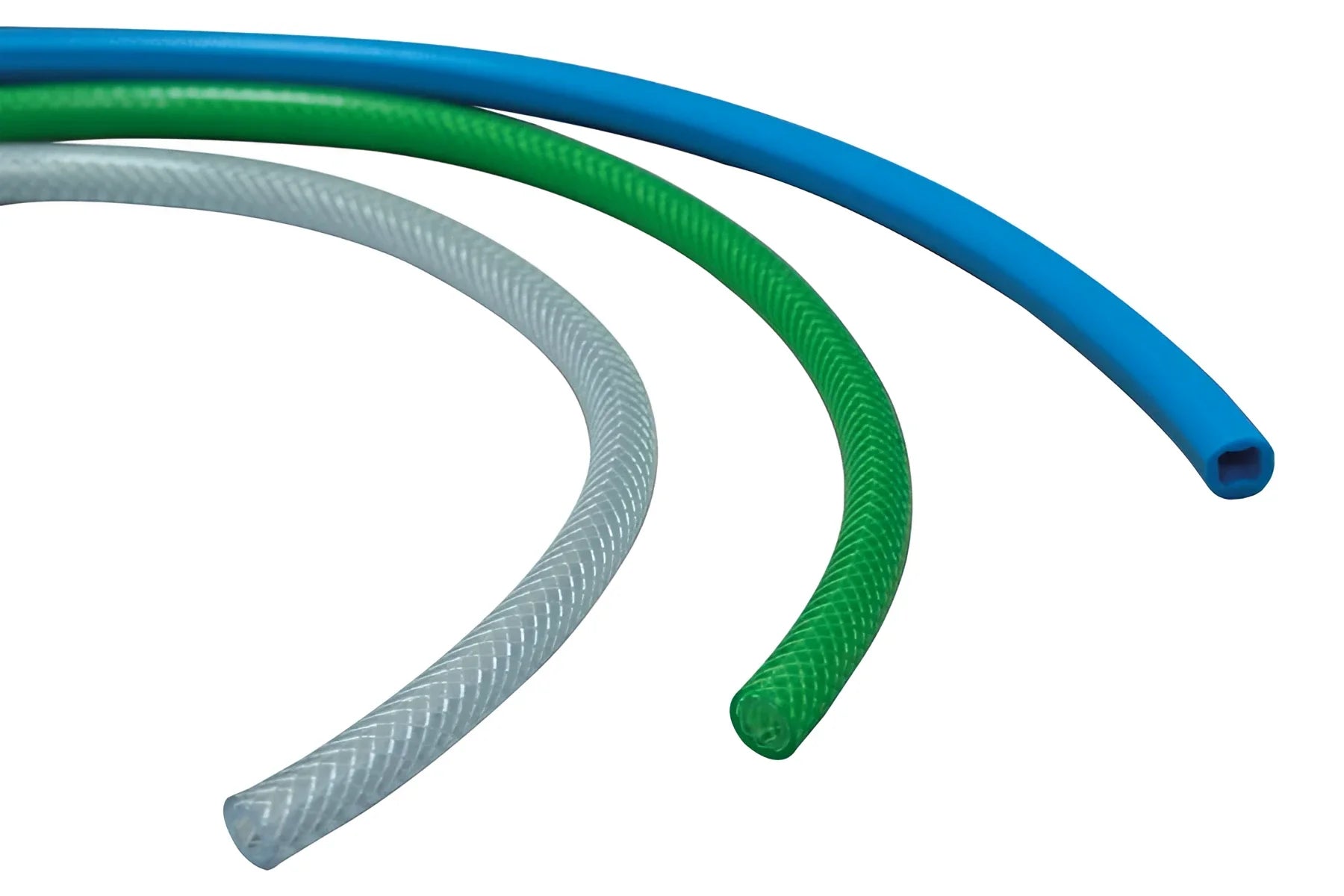

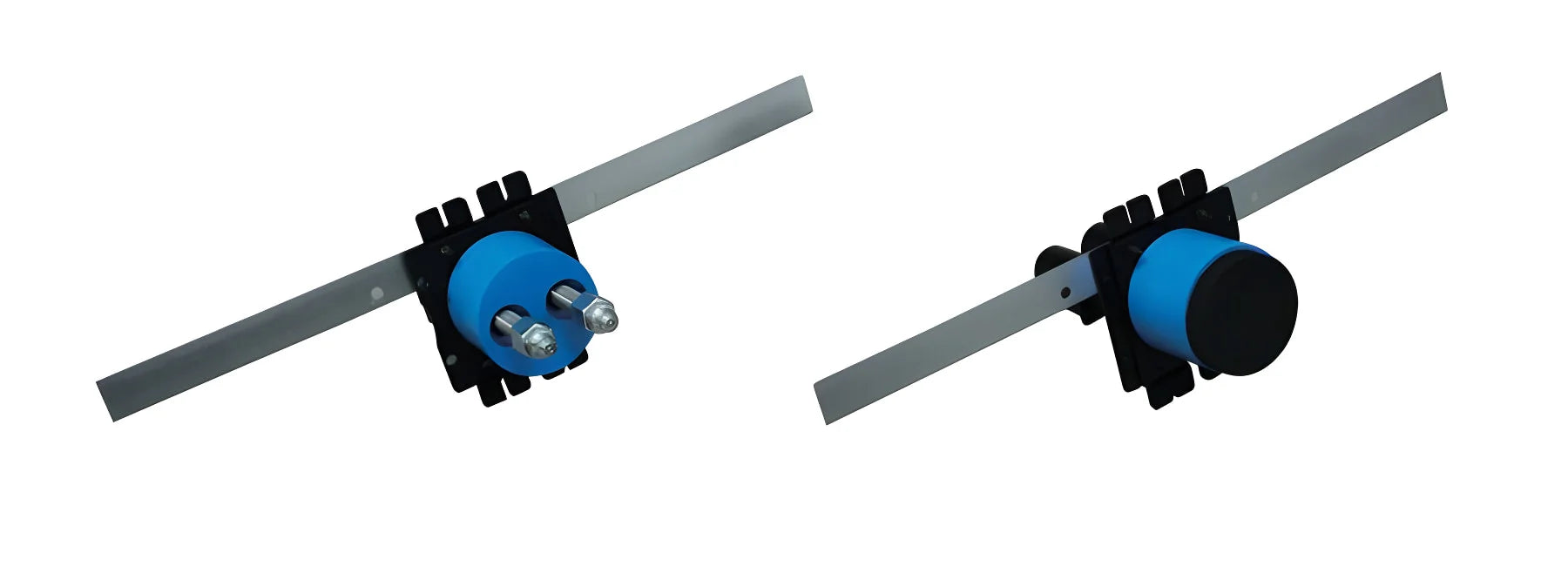

This high-performance injection hose features micro-ports spaced evenly across its entire circumference. When injection resin is applied at 1-bar pressure or higher, these ports open to allow the low-viscosity resin to deeply penetrate and seal the surrounding concrete, ensuring long-lasting water resistance.

Key Benefits:

✔ Superior Water Resistance – Resistant to permanent water pressure of 2 bar, providing a watertight joint seal.

✔ Compatible with Multiple Resins – Works effectively with polyurethane and acrylic injection resins such as Newton 322-SP and Newton 323-SA.

✔ No Structural Displacement – The injection hose remains intact and undisturbed during concrete compaction.

✔ Labour & Cost Efficient – Eliminates the need for a kicker or rebate, reducing site labour costs.

✔ Durable & Weatherproof – The injection hose withstands exposure to weather and site work delays without compromising performance.

✔ Guaranteed Flow & Deep Sealing – The star-shaped interior geometry ensures continuous flow of resin even when navigating sharp bends.

✔ Quicker to Install – More efficient than conventional waterbars, reducing installation time.

✔ Prevents Reinforcement Corrosion – Seals the entire joint rather than just the immediate area, preventing water from reaching reinforcement steel.

✔ Chemical Resistance – Resistant to sewage, chlorine, and sulphides, making it ideal for aggressive environments.

✔ Long-Term Integrity – Not affected by wet/dry cycles and maintains sealing effectiveness for the lifetime of the structure.

✔ No Swelling Issues – Unlike bentonite-based waterbars, it will not free-swell into voids and wash away.

Typical Applications:

🔹 Concrete walls supported from a raft – With or without a kicker.

🔹 Within concrete walls – For maximum structural integrity.

🔹 Within concrete rafts or slabs – Ensuring permanent waterproofing.

🔹 Concrete slab to piled walls – Providing reliable joint sealing.

🔹 Concrete slab to brick/block wall – Enhancing structural resilience.

Suitable Substrates:

✔ Reinforced Concrete – Standard and water-retaining structures.

✔ Steel Piled Walls – Welded flange required.

✔ Brick or Concrete Block Walls – Suitable for various construction settings.

Technical Data:

| Feature | Result |

|---|---|

| Material | Formulated closed-cell plastic |

| Colour | Light Blue |

| Profile | Round with 4 x semi-circular notches |

| External Diameter | 13.0mm |

| Internal Diameter | 6.0mm |

| Micro-Port Length | 5.0mm |

| Micro-Port Spacing | 15mm |

| Micro-Port Opening Pressure | > 1 bar |

| Application Temperature | -10 to +50°C |

| Service Temperature | -10 to +50°C |

| Minimum Required Concrete Cover | 100mm |

| Water Resistance (Sealed with Newton 322-SP) | 2 bar |

| Maximum Installed Hose Length | 10-12m |

| Packaging – Coils | 120m |

Available Variants & Packaging:

✔ HydroTank 302 Injection Hose (Code: 302) – 120m coils

✔ HydroTank 302K60 Injection Hose Kit (Code: 302K60) – 60m injection hose kit

✔ HydroTank 302K120 Injection Hose Kit (Code: 302K120) – 120m injection hose kit

📞 Need expert advice? Contact our technical support team at 01268 472358 for guidance on product selection, installation support, and bulk order pricing.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Security

You may also be interested in

Recently viewed

What Our Customers Say

Very good 4.7/5

Exceptional Advice & Support

Hands down in all of my reviews I've done in 21+ years, Clever Shield Coatings is one I'll always remember as the staff are friendly & passionate about their job - looking out for the customer and getting the job done right first time.

Sunny

Verified customer

Fast, friendly and reliable…

Fast, friendly and reliable. I was able to get my job done quickly and my customer was happy with the prices.

Thanks.

Kamil

Verified customer

Exceptional Advice & Support

We have been using clever shield (dealing with Richard) for over 2 years. They always give good service deliveries on time and even give technical advise when needed.

JAC

Verified customer

Really helpful! great service

Spoke to technical for some advice on the product and it was really helpful, great service

Tina Mansfield

Verified customer

Great company / knowledgeable

What a great company - knowledge about the products, spent lots of time talking me through everything - if only every company was like this one !

Ostler Info

Verified customer

Great company and speedy delivery

Really great company to deal with,excellent customer service,speedy delivery will definitely recommend and use again as a satisfied customer

Del Upson

Verified customer

Great Technical Support

Great technical support and advice on wykamol products would highly recommend this company

Shirley

Verified customer

Highly Recommended

Sandra Dow

Verified customer